Risk-Based Inspection (RBI): Smarter Inspections That Save Time and Money

In today’s high-stakes industrial environments, not all equipment poses the same risk. So why inspect everything the same way?

Risk-Based

Inspection (RBI) offers a smarter alternative—one that prioritizes

inspection resources based on the actual risk of failure. It shifts the

focus from time-based routines to risk-driven planning, helping

companies optimize safety, reduce costs, and improve uptime.

🔍 What Is RBI?

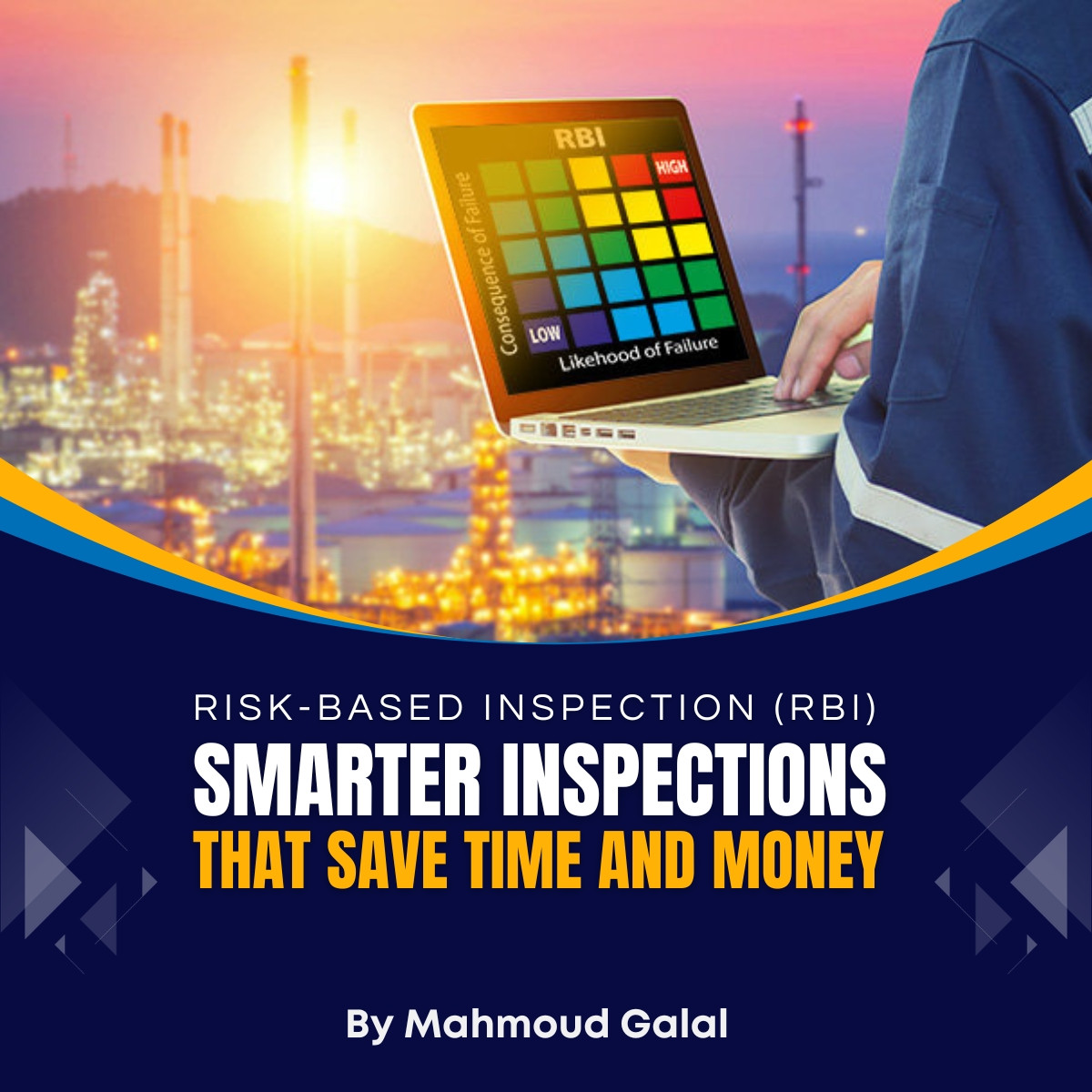

At its core, RBI is a decision-making tool that evaluates:

• Likelihood of failure (based on degradation mechanisms, age, usage, etc.)

• Consequence of failure (impact on people, environment, production)

This

data-driven approach allows teams to rank assets, so high-risk items

get more attention, and low-risk ones are monitored more efficiently.

⚙ RBI in Action: Key Steps

• Asset Identification – Define the systems and components to be analyzed.

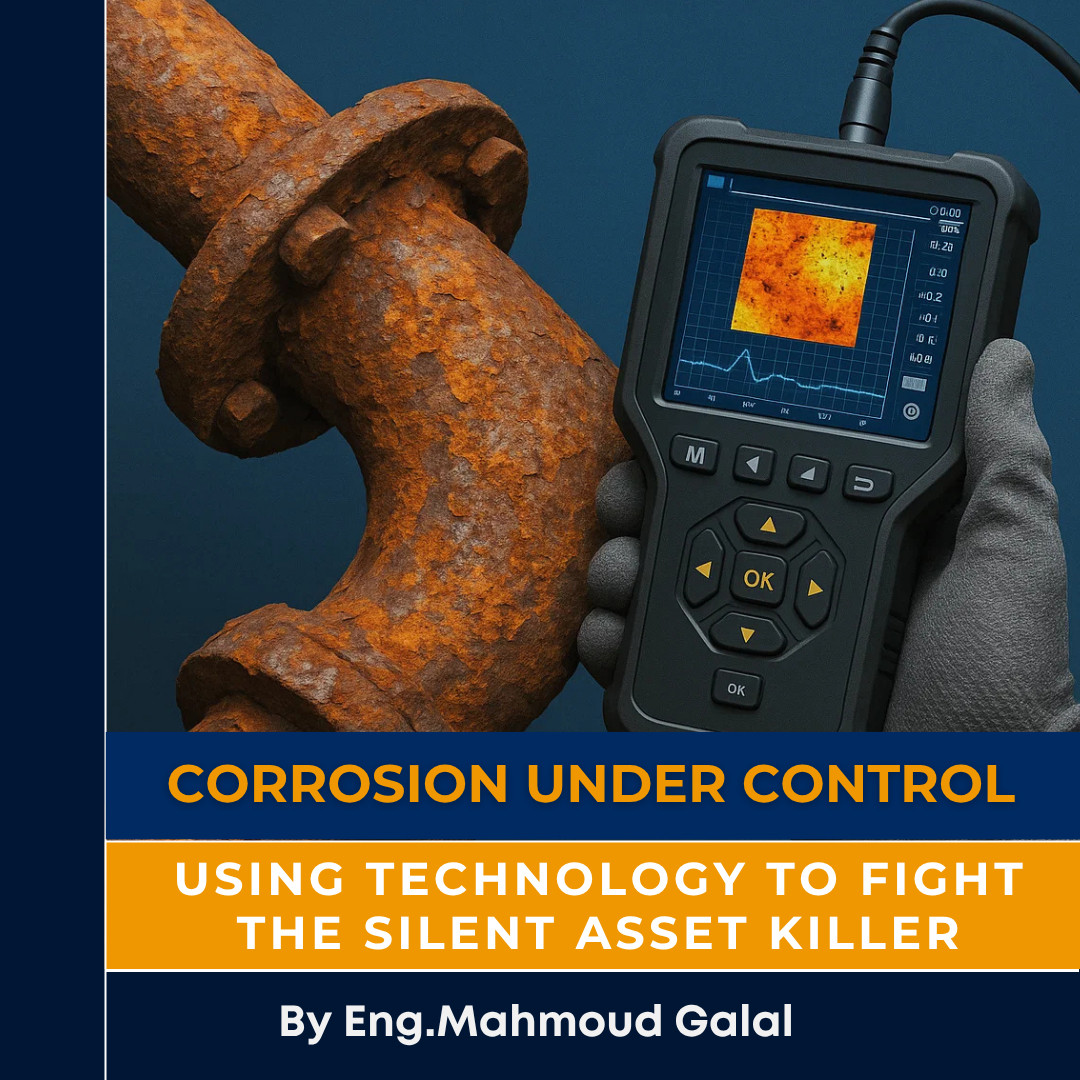

• Threat Evaluation – Understand failure modes (corrosion, fatigue, etc.).

• Risk Assessment – Score probability and consequence of failure.

• Inspection Planning – Tailor inspection type, frequency, and method.

• Mitigation & Follow-Up – Act on findings with repair, replacement, or redesign.

Many organizations integrate RBI with software platforms that streamline data collection, visualization, and risk scoring.

🚀 Benefits of RBI

✔ Reduced Inspection Costs

Focus time and resources on critical areas, avoiding blanket inspections.

✔ Increased Asset Availability

Smarter planning leads to fewer unplanned shutdowns.

✔ Better Use of Data

Incorporates operational history, inspection findings, and real-time input.

✔ Improved Safety & Compliance

Addresses high-risk items proactively—before they cause harm.

🔄 RBI + Technology = Next-Level Insight

When RBI is enhanced with AI, digital twins, and IoT sensors, it becomes even more powerful:

• Predict failure trends

• Update risk profiles in real-time

• Simulate inspection strategies before deployment

🛠 RBI in Action

Let’s

say you have two identical heat exchangers. One handles high-pressure,

corrosive fluid. The other handles water at low temperature. RBI would

flag the first as high risk, and the second as low. This way,

inspections are driven by operating conditions—not equipment type alone.

🚧 Challenges to Consider

• Data Quality: Poor records lead to poor risk decisions.

• Initial Effort: Setting up RBI takes time and teamwork from inspection, process, and safety teams.

• Training: Everyone involved must understand RBI concepts to apply them correctly.

•

🔄 Final Thought

RBI

is not just a trend—it’s a smarter way to manage inspection resources

in complex operations. If you’re still inspecting everything the same

way, it may be time to shift from routine to risk-driven.

RBI

isn't just a tool—it's a mindset shift. It asks us to be strategic, not

routine. For any organization aiming to modernize its integrity

management, RBI is a crucial first step toward data-driven reliability

and operational excellence.

Next article: “Digital Twins in AIM: From Concept to Field Application”

Has your team adopted RBI yet? What challenges did you face in implementation?

Drop your thoughts below ⬇ or message me—we’d love to hear your story.

0 comments